PRODUCT OFFER

- Rolled material

- Billet

- Steel bar

- Rolled black

- Peeled material

- Drawn material

- Pipes

- Rolled seamlessly

- Drawn seamlessly

- Flat steel

- Wire rod

- Forged material

- Continuous casting

- Quality & high-grade engineering steel

- Spring steel

- Micro-alloyed & alloyed steelsSpecial

- rades

- Rods

- With round, square or rectangular cross-sections

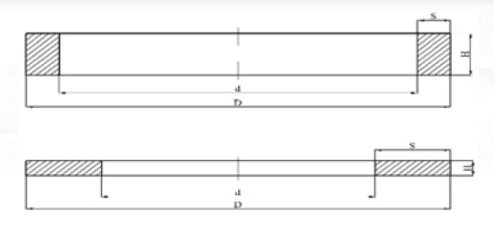

- Sleeves forged on a mandrel

- Discs with and without holes

- Expansion rings

- Cube and rectangular

- Metallurgical rollers

- Propeller shafts, intermediate shafts, generator shafts, oar bars

- Other forgings with moulds

- Flange shafts

The forgings are made from the following types of steel: Carbon steel, alloy steel, quenched and tempered steel, case hardening steel, bearing steel, hot and cold work steel. According to the following standards: PN, EN, DIN, ASTM, AISI, SAE.

Our Polish supplier delivers the forged parts: Thermally treated, raw (without mechanical treatment), after mechanical treatment. The products are subjected to the following tests: control of mechanical properties, ultrasonic testing, microscopic examination. The input material used for the manufacture of the products comes from both domestic and foreign producers who have the required ISO certificates and approvals from classification societies.

New in the program: Rings

This production programme is an innovative, low-waste technology for machining large rings using rolling and forging processes, which is developed and verified under real conditions. The solution obtained enables rings with a diameter of up to 3800 mm and a height of up to 800 mm to be produced with a complex cross-sectional geometry consisting of a whole spectrum of steel grades including special steels and non-ferrous metal alloys. The rings are, for example, from the common grades C45, S355J2G3, 42CrMo4, 34CrNiMo6 and 30CrNiMo88. Many other materials are also in use and can of course be requested. The products can be manufactured as almost finished products with minimal tolerance. The new processing line, together with a unique defect detection station and an automated material transfer system, enables the production of ring products with minimal processing allowances, which are characterized by a uniform material structure over the entire cross section.

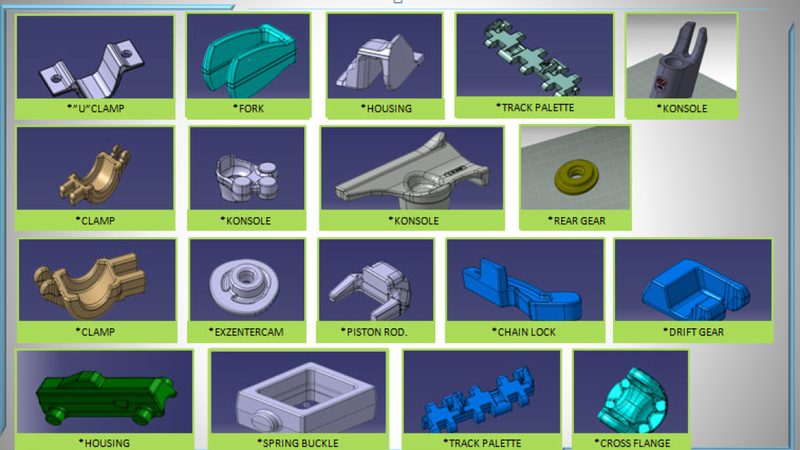

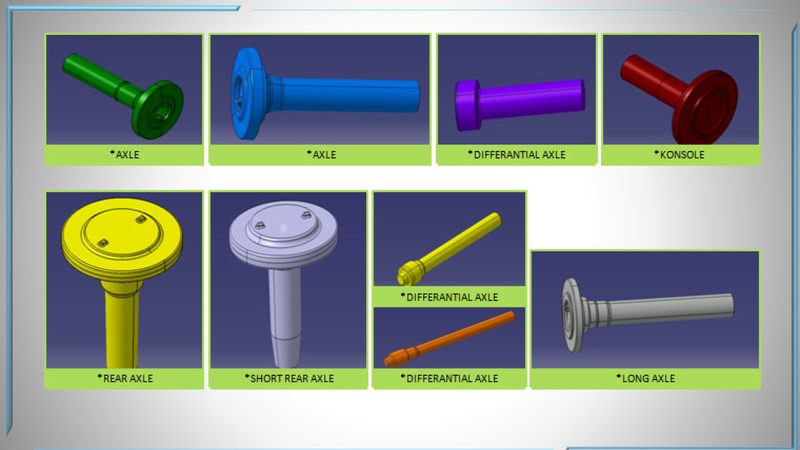

- Cardan shafts

- Axle beams

- Crankshafts

- Steering arms / forks

- Cardan forks

- Pull rods

- Connecting rods

- Release arms

- Gear shafts

- Clamps

- Hooks

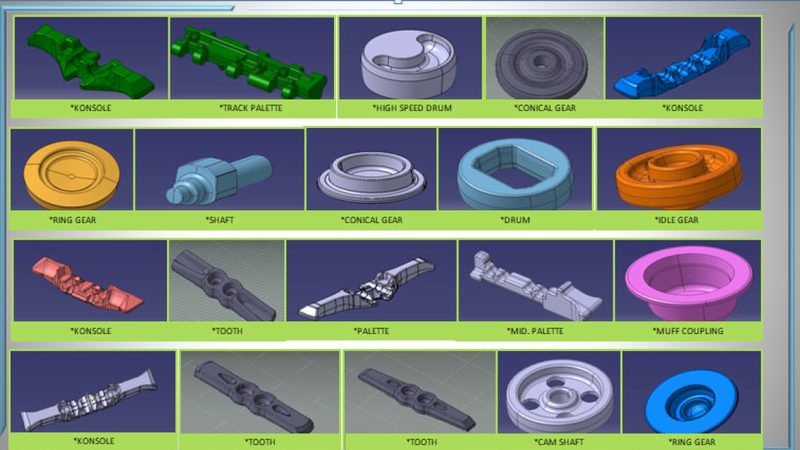

- Cogs

- Beams

- Gear body

- Conveyor chains

- Gear forks

With a capacity of 20,000 tons, the high quality drop forge manufactures parts for the automotive, railway and mining industries.

The Turkish forge has a wide range of system configurations with hammers and presses, its own toolmaking facility and machining. The weight class goes from a part weight of 500 grams to 80 kilograms as well as mechanical processing.

With modern technology, high production capacity and first-class infrastructure, the company is a technologically leading manufacturer of forged parts. The activities consist of:

- Forging

- Manufacturing

- Cutting processes

- Forming technology

- Heat treatment

- Further processing

- Processing

- Inspection and monitoring

- Designs for weight reduction

- Development of new products

- Special assemblies